Virgin Kiteboard Project - da theory

Learning how to model a kiteboard. The goal, better DIY kiteboards.

Sunday, September 11, 2011

Manufacturing variation in fibreglass

Cam across this paper showing the magnitude of property variation by manufacture of fibre glass. Could be useful in setting lower working limits on output from Board-off felx modeling.

Manufacturer variation in Fibreglass

Monday, June 20, 2011

Wednesday, June 1, 2011

Modelling Composite Material

As is the theme of the model we're developing, we are going to work with a model of composites that is widely used but probably popular primarily because of its simplicity. Models of composite behaviour are the subject of more than a lot of PhD's but for the narrow range of operating environments and the simple needs we have of the model the so called 'Slab Model' and the associated 'rules of mixtures' will serve more than adequately.

The Slab Model can be applied to any composite material that is made up of reinforcement ( such as fibreglass, carbon or steel mesh/ reo) that is encapsulated inside a Matrix material such as resin or concrete. The model consists of separating the reinforcement and the matrix into 2 separate slabs that are layered either one on top of the other or side by side and fixed together. Each component of the Slab occupies the same volume as it does in the actual material. The composite slab is then subject to the common strain constraint and the common stress constraint respectively.

The constant strain assumption is used when the load is in the same direction as the (long) fibres. This is because the fibres and the resin work in parallel to take the load and so must stretch by the same amount when loaded. The constant stress constrain is typically used when the loading is perpendicular to the direction the long fibres run as in this cast the resin and fibres are working in series ( cross-sections of the fibres joined with resin in between them) and so are both subject to the same stress ( i.e the same forces).

As the name suggests the common strain constraint means that under load (typically tensile load) both layers of the slab experience the same amount of strain. That is, the percentage elongation of the material is the same. This makes intuitive sense as the composite material will elongate as a whole. As we are only working with the linear region of elasticity we have the simple relationship between stress and strain where Stress/Strain = Elastic Modulus. As the reinforcements' elastic modulus much great than that of the resin ( c. 70GPa vs 2-3 GPa) the constant strain assumption implies that the stress in the higher modulus material ( the glass/carbon) will be much greater than that in the resin. That is, the reinforcement will do what reinforcement is supposes to do and that is take the lions share of the stresses the composite is exposed to.

Many physical parameters of the composite material can be estimated by taking into account the volume weighted contribution of each of the components of the slab. These are referred to as the 'Rules of Mixtures'. One simply takes the volume fractions of each component of the slab, multiplies the relevant physical parameter and sums them to get the approximate value of that parameter for the composite material.

When applying these you do need to think about the geometry of the situation you're working with. Unlike the Euler-Bernoulli Beam equation there is no term like the Area Moment of Inertia to take care of the geometrical considerations and you need to build up each case from 'first principals' and apply that appropriate assumptions for the arrangement.

For example, suppose that you wanted to estimate the elastic modulus under tension of unidirectional glass/ resin under axial load ( loaded along the long axis of the fibres) then you could just apply the rules of mixtures to calculate the volume weighted sum of the elastic modulus of each slab component. However, what about woven fabric where there fibres run in both directions? The load applied perpendicular to the load axis of the board which you would have used the constant stress assumption for now has fibres running across the width of board and so would be subject to the constraint strain assumption. Which is right? As the lateral distortion of the material will ultimately be constraint by the constant strain assumption governing the elongation of the width-wise fibres it is inconsistent with the constant strain assumptions as the 'series co-operation' that leads to the constants stress assumption would be subject to the constant strain assumptions being applied to the width-wise fibres. In this case you would use the constant strain assumption and the additional impact of the length-wise reinforcement would be taken into account by the volume fraction of the total volume of reinforcement (the sum of both direction-lying glass).

For our model the axial (long axis) elastic modulus (the elastic modulus in the direction of the boards-length) will be the most important parameter we will estimate this way as this is the value we need to plug into the Beam equation to determine the flex profile. However, many more can be estimated using the rules of mixtures.

Because the discussion of the various aspects of the model are limited to the requirements of our simple model, there are a number of effects that are being ignored. These effects are relatively small for the range operating parameters we are restricting ourselves to. In particular, we have assumed that the board will not be subject to strong shear forces that would distort the cross-sections (an requirement of the beam equation). This is reasonable in our case because the shear forces in the direction of the long axis of the board ( i.e perpendicular to the cross-section of the board are negligible and the board would snap long before the bending of the board could induce shear forces in this plane. The fact that the shear forces due to the lateral distortion that comes about when you strain a material in the normal direction ( the constant of proportionality is called Poisson's Ratio) is negligible compared to the strain due to axial loading.

The Slab Model can be applied to any composite material that is made up of reinforcement ( such as fibreglass, carbon or steel mesh/ reo) that is encapsulated inside a Matrix material such as resin or concrete. The model consists of separating the reinforcement and the matrix into 2 separate slabs that are layered either one on top of the other or side by side and fixed together. Each component of the Slab occupies the same volume as it does in the actual material. The composite slab is then subject to the common strain constraint and the common stress constraint respectively.

The constant strain assumption is used when the load is in the same direction as the (long) fibres. This is because the fibres and the resin work in parallel to take the load and so must stretch by the same amount when loaded. The constant stress constrain is typically used when the loading is perpendicular to the direction the long fibres run as in this cast the resin and fibres are working in series ( cross-sections of the fibres joined with resin in between them) and so are both subject to the same stress ( i.e the same forces).

As the name suggests the common strain constraint means that under load (typically tensile load) both layers of the slab experience the same amount of strain. That is, the percentage elongation of the material is the same. This makes intuitive sense as the composite material will elongate as a whole. As we are only working with the linear region of elasticity we have the simple relationship between stress and strain where Stress/Strain = Elastic Modulus. As the reinforcements' elastic modulus much great than that of the resin ( c. 70GPa vs 2-3 GPa) the constant strain assumption implies that the stress in the higher modulus material ( the glass/carbon) will be much greater than that in the resin. That is, the reinforcement will do what reinforcement is supposes to do and that is take the lions share of the stresses the composite is exposed to.

Many physical parameters of the composite material can be estimated by taking into account the volume weighted contribution of each of the components of the slab. These are referred to as the 'Rules of Mixtures'. One simply takes the volume fractions of each component of the slab, multiplies the relevant physical parameter and sums them to get the approximate value of that parameter for the composite material.

When applying these you do need to think about the geometry of the situation you're working with. Unlike the Euler-Bernoulli Beam equation there is no term like the Area Moment of Inertia to take care of the geometrical considerations and you need to build up each case from 'first principals' and apply that appropriate assumptions for the arrangement.

For example, suppose that you wanted to estimate the elastic modulus under tension of unidirectional glass/ resin under axial load ( loaded along the long axis of the fibres) then you could just apply the rules of mixtures to calculate the volume weighted sum of the elastic modulus of each slab component. However, what about woven fabric where there fibres run in both directions? The load applied perpendicular to the load axis of the board which you would have used the constant stress assumption for now has fibres running across the width of board and so would be subject to the constraint strain assumption. Which is right? As the lateral distortion of the material will ultimately be constraint by the constant strain assumption governing the elongation of the width-wise fibres it is inconsistent with the constant strain assumptions as the 'series co-operation' that leads to the constants stress assumption would be subject to the constant strain assumptions being applied to the width-wise fibres. In this case you would use the constant strain assumption and the additional impact of the length-wise reinforcement would be taken into account by the volume fraction of the total volume of reinforcement (the sum of both direction-lying glass).

For our model the axial (long axis) elastic modulus (the elastic modulus in the direction of the boards-length) will be the most important parameter we will estimate this way as this is the value we need to plug into the Beam equation to determine the flex profile. However, many more can be estimated using the rules of mixtures.

Because the discussion of the various aspects of the model are limited to the requirements of our simple model, there are a number of effects that are being ignored. These effects are relatively small for the range operating parameters we are restricting ourselves to. In particular, we have assumed that the board will not be subject to strong shear forces that would distort the cross-sections (an requirement of the beam equation). This is reasonable in our case because the shear forces in the direction of the long axis of the board ( i.e perpendicular to the cross-section of the board are negligible and the board would snap long before the bending of the board could induce shear forces in this plane. The fact that the shear forces due to the lateral distortion that comes about when you strain a material in the normal direction ( the constant of proportionality is called Poisson's Ratio) is negligible compared to the strain due to axial loading.

Tuesday, May 31, 2011

Monday, May 23, 2011

Couple of useful references on simple bending

Good introduction with some worked examples:

http://courses.washington.edu/me354a/chap3.pdf

Good overview that puts the simple bending in context of more complex bending including shear forces and dynamic forces.

http://en.wikipedia.org/wiki/Bending

Another good source

http://en.wikipedia.org/wiki/Euler%E2%80%93Bernoulli_beam_equation

http://courses.washington.edu/me354a/chap3.pdf

Good overview that puts the simple bending in context of more complex bending including shear forces and dynamic forces.

http://en.wikipedia.org/wiki/Bending

Another good source

http://en.wikipedia.org/wiki/Euler%E2%80%93Bernoulli_beam_equation

Sunday, May 22, 2011

A short reflection on the model so far

So far we've set up or model based on a simply implementation of the Bernoulli - Euler beam equation.

We're only considering bending due to moments created by forces applied in the vertical direction and have ignored bending due to shear forces acting on the board (which in most cases is reasonable). The model is a small deflection model (and we need to keep our eye on this) and is a based on linear elasticity ( i.e it assumes that the elastic properties can be modelled by simple springs).

According to the wikipedia source ( I have not confirmed ) the large diflection considerations only need to be applied when the radius of curvature at any point is less than 10 times the baord thickness. In our case this is going to less than 15 cm which obviously we would never reach.

Thinking about stiffness in terms of E,I and L, gives quite a usable way of thinking about designing flex. Although the model is (necessarily) simple you canhopefully see that it has already provides some great insights into the relationship between many of the board parameters that we play with when designing boards: E captures the contribution of the core materials, I the geometry including concave and channels, width thickness and L the length.

One glaring omission from this list is the laminate and layup schedule ( i.e how many layers, what orientation the fibres have, the type of resin and reinforcement etc). The answer fairly obviously lies in the the values and way you use E.

Unfortunately, its not quite as straightforward as constructing the value of 'I' by building up more complex shapes by adding and subtracting various pieces. While we do build up a piecemeal model of the 'E' structure of the core the laminate itself needs a simplifying model to make dealing with the complexities of the load transfer between the resin and reinforcement. We are of course going to choose the simplest model ( good old engineers approach!) called the Slab Model which will yield an 'effective' E for the composite material that we will be able to make use of in building up our 'jigsaw' of different 'E' materials.

We're only considering bending due to moments created by forces applied in the vertical direction and have ignored bending due to shear forces acting on the board (which in most cases is reasonable). The model is a small deflection model (and we need to keep our eye on this) and is a based on linear elasticity ( i.e it assumes that the elastic properties can be modelled by simple springs).

According to the wikipedia source ( I have not confirmed ) the large diflection considerations only need to be applied when the radius of curvature at any point is less than 10 times the baord thickness. In our case this is going to less than 15 cm which obviously we would never reach.

Thinking about stiffness in terms of E,I and L, gives quite a usable way of thinking about designing flex. Although the model is (necessarily) simple you canhopefully see that it has already provides some great insights into the relationship between many of the board parameters that we play with when designing boards: E captures the contribution of the core materials, I the geometry including concave and channels, width thickness and L the length.

One glaring omission from this list is the laminate and layup schedule ( i.e how many layers, what orientation the fibres have, the type of resin and reinforcement etc). The answer fairly obviously lies in the the values and way you use E.

Unfortunately, its not quite as straightforward as constructing the value of 'I' by building up more complex shapes by adding and subtracting various pieces. While we do build up a piecemeal model of the 'E' structure of the core the laminate itself needs a simplifying model to make dealing with the complexities of the load transfer between the resin and reinforcement. We are of course going to choose the simplest model ( good old engineers approach!) called the Slab Model which will yield an 'effective' E for the composite material that we will be able to make use of in building up our 'jigsaw' of different 'E' materials.

Flexural Rigidity 'Stiffness'

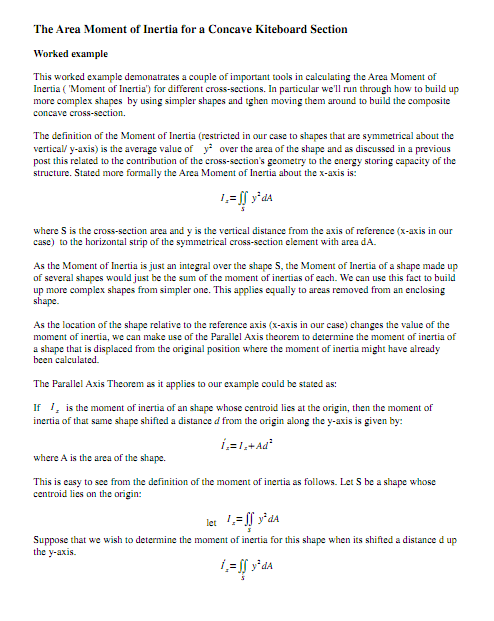

In the last post we did a preliminary exploration of the Area Moment of Inertia which arises in beam bend theory as is colloquially referred to as a beam resistance to bending. This comes about because if you recall the Bernoulli-Euler beam equation, in our simple situation it can be integrated twice to give a second order differential equation (ie involving the second derivative of the deflection) and when you rearrange it you end up with

d^2w/dx ^2= 1/(EI) M(x)

where d^2w/dx^2 is the second derivative of the deflection w and M(x) is the moments (force times the distance to the force) that the cross-section at x are subject to.

The second derivative can be shown (for our model) to be equal to 1 over the radius of curvature at that point. That is, the radius of curvature at x is proportional to I. Therefore, the greater the value of I the larger the radius of curvature and hence the lower the amount of deflection (i.e stiffer board).

One example was give of introducing concave which added an additional positive terms to the I of a standard rectangular section and hence made the board stiffer. It can be demonstrated that when you add concave of about 95% of the thickness you double the 'stiffness'. Concave can be thought of as artificial thickness.

The resistance to bending is also proportional to E, the elastic modulus of the material. Again, stiffer material, higher E, less flex.

The product of E*I (x) is a very useful figure and is referred to as the flexural rigidity of the structure. More often than not this is what people mean when they refere to 'stiffness'. E and I are the primary parameters available for changing the stiffness of the board assuming that the length of the board is subject to other design constrains such as planing area or the like.

It is worth noting that the length of the board also makes a significant impact on the overall flex of the board.

To see this first consider the beam equation as its written above. Suppose that there is just a single point force being applied right at the tip of magnitude F and suppose that the half length of the board is L. Just for illustration purposes suppose that EI is constant along the length of the board ( that is no taper). In this case the moment at the center of the board is FL. Integrating the beam equation along the board from the middle to the tip of the board twice (remember its a second derivative involved) yields a deflection value (at the middle point) of

FL^3/(2EI)

What this shows is that the deflection is proportional to the length (in our case the half length) cubed.

Of course, if you do the same exercise for a point further down the board the effective value of L reduces (it is the distance from the point your considering to the tip) and so the amount of deflection experienced by the slither of cross-section your looking at reduces and so the local radius of curvature tends to increase (i.e get flatter towards tips and hence why we need to thin the tips of the board out to make sure they flex and don't just transfer the moments they experience back to the center section of the board).

d^2w/dx ^2= 1/(EI) M(x)

where d^2w/dx^2 is the second derivative of the deflection w and M(x) is the moments (force times the distance to the force) that the cross-section at x are subject to.

The second derivative can be shown (for our model) to be equal to 1 over the radius of curvature at that point. That is, the radius of curvature at x is proportional to I. Therefore, the greater the value of I the larger the radius of curvature and hence the lower the amount of deflection (i.e stiffer board).

One example was give of introducing concave which added an additional positive terms to the I of a standard rectangular section and hence made the board stiffer. It can be demonstrated that when you add concave of about 95% of the thickness you double the 'stiffness'. Concave can be thought of as artificial thickness.

The resistance to bending is also proportional to E, the elastic modulus of the material. Again, stiffer material, higher E, less flex.

The product of E*I (x) is a very useful figure and is referred to as the flexural rigidity of the structure. More often than not this is what people mean when they refere to 'stiffness'. E and I are the primary parameters available for changing the stiffness of the board assuming that the length of the board is subject to other design constrains such as planing area or the like.

It is worth noting that the length of the board also makes a significant impact on the overall flex of the board.

To see this first consider the beam equation as its written above. Suppose that there is just a single point force being applied right at the tip of magnitude F and suppose that the half length of the board is L. Just for illustration purposes suppose that EI is constant along the length of the board ( that is no taper). In this case the moment at the center of the board is FL. Integrating the beam equation along the board from the middle to the tip of the board twice (remember its a second derivative involved) yields a deflection value (at the middle point) of

FL^3/(2EI)

What this shows is that the deflection is proportional to the length (in our case the half length) cubed.

Of course, if you do the same exercise for a point further down the board the effective value of L reduces (it is the distance from the point your considering to the tip) and so the amount of deflection experienced by the slither of cross-section your looking at reduces and so the local radius of curvature tends to increase (i.e get flatter towards tips and hence why we need to thin the tips of the board out to make sure they flex and don't just transfer the moments they experience back to the center section of the board).

Subscribe to:

Comments (Atom)